Satellite communication is growing rapidly. Recent and anticipated launches of new satellite equipment are spurring interest in and demand for wireless communication. Several companies have stated the intent to provide large throughput, high-speed communication networks in the coming years. Along with the increased access to space, this is driving interest in new satellite communications. Accordingly, we need new communications technology to supply bandwidth and data rate to support these applications.

The Need for More Bandwidth

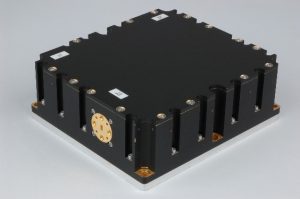

W-Band (94 GHz) 50-Watt SSPA prototype for space-based cloud profiling radar.

One challenge is the need for more bandwidth to handle the increasing number and increasing size of data transmissions. Our increasingly connected world is data hungry. For example, with 4K and 8K video, autonomous vehicles, 5G, the Internet of Things, and much more, we simply need more data. The more data a satellite can provide, the more customers it can handle and applications it can facilitate. In addition to consumer-driven and defense-driven demand, scientific research, such as global efforts in space-based Earth sciences—climate studies, agricultural and industrial imaging and more—require considerable data transmission. The on-board satellite sensors require millimeter-wave (mmW) communication to transmit large amounts of data back to Earth. To transmit this data quickly requires bandwidth.

Bandwidth can be increased in a few different ways. One of the most obvious ways is to increase the carrier frequency of transmission. This push for more bandwidth requires frequencies such as mmW, which allows for wider bandwidth and smaller antennas. Regulatory bodies have recently added new bands that include frequencies in the mmW range up to around 100 GHz, driving the interest in exploring these added frequency territories and beyond.

Limits of Existing Technology

Current satellite data transmissions use traveling wave tube amplifiers (TWTAs). These tubes, while a well-established technology, have limitations. One limitation is the frequency at which they can operate. The performance of TWTAs degrades above 50 GHz. This is a serious limitation when it comes to moving to higher frequency and bandwidth. In addition to the frequency restriction, TWTAs are large and heavy, and require high-voltage power supplies. This makes them less reliable. Furthermore, TWTAs are expensive. In short, these characteristics not favorable for a space satellite.

Solid-State mmW Amplifiers

V-Band (58 GHz) SSPA for space communications.

While TWTAs have played and will continue to play an important role in microwave satellite communication, we need new technology as we push into mmW frequencies. Much like the tube technology of early electronics, the new trend is a shift toward solid-state electronics. See NASA Spinoff Database: Power Amplifiers Boost Radar, Communications, Defense Systems.

Gallium nitride (GaN) and gallium arsenide (GaAs) semiconductor technology has the potential to supply space-qualified and robust solid-state power amplifiers (SSPAs) for high frequencies and high power. Today, GaAs is widely used in SSPAs at lower frequencies in applications requiring low to moderate output power levels; however, heat can limit its power output. GaN power amplifiers are a relatively new technology still in development. They have the potential to produce more power output than GaAs amplifiers, since they can operate at higher temperatures.

Although GaN can produce significantly higher power levels with good efficiency, its power output is still much lower than is desired for satellite communications. Combining the output of many devices into one power amplifier solves this issue.

Combining Outputs

8-way divider/combiner.

The power output can be combined in several different ways. For example, these include spatial methods, radial, corporate, on-chip, waveguide and others. Producing GaN power amplifier circuits and combining the outputs requires a unique blend of mechanical and electrical expertise. At high frequencies, the mechanical design is integral to the electrical design, such that they are one and the same. This requires expertise that understands both disciplines and can simulate and build a product while understanding the results. In many cases, some companies specialize in mechanical combining structures, while others specialize in Microwave Monolithic Integrated Circuit (MMIC) design. Producing a mmW SSPA that utilizes GaN and GaAs requires a manufacturer with expertise in both disciplines.

QuinStar SSPAs

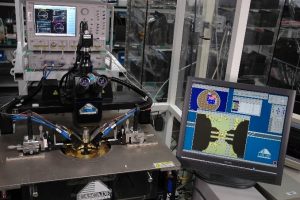

Wafer-probe station enables one-sweep testing over 7 KHz to 145 GHz.

At the present time, few companies are positioned to effectively produce SSPAs based on GaN and GaAs. But QuinStar is a leader in this field and has the unique mix of talent and equipment necessary to drive innovation and production of MMICs. QuinStar designs and manufactures microwave and mmW components and multi-functional modules. QuinStar effectively leverages its proprietary technology and experience to fully exploit the advantages of GaN’s high microwave power capability to produce state-of-the-art SSPAs. They are not just a components company; QuinStar is a leading innovator in mmW SSPA technology. Central to that technology is the development of state-of-the-art MMICs. QuinStar designs their MMICs for fabrication by foundries. After that, QuinStar packages and implements the MMICs in a proprietary way to realize the required bandwidth and power.

Fast and Flexible

Precision machine shop supports synchronous optimization.

To achieve the level of prototyping and production required, the ability to change directions quickly—and to fabricate and modify parts—is paramount. Therefore, vertically integrated capabilities to support the design engineers with simulation, fabrication and analysis capacities is the key. High-power, GaN-based SSPAs require the synchronous optimization of several different technologies such as high-power ferrite devices, low-loss custom waveguide fabrication, power combiners, power supply conditioning circuits and MMICs. Effectively developing a unique product that relies on emerging technology requires keeping essential processes in-house. This allows the company to be fast and flexible with design improvements.

Innovative SSPAs from the Industry Leader

In conclusion, when a unique application requires a revolutionary SSPA solution, it requires a full-service engineering and manufacturing partner. The aerospace engineers who started QuinStar in 1993 wanted to design and build challenging equipment. QuinStar is focused on growing its operations and maintaining production in the United States. QuinStar designs, develops and produces application-specific MMICs, SSPAs and transceiver modules that enable the development of complex systems—today and into the future.